Prepared in collaboration with Kara Steshetz, Ayush Agarwal and Marina Miletic

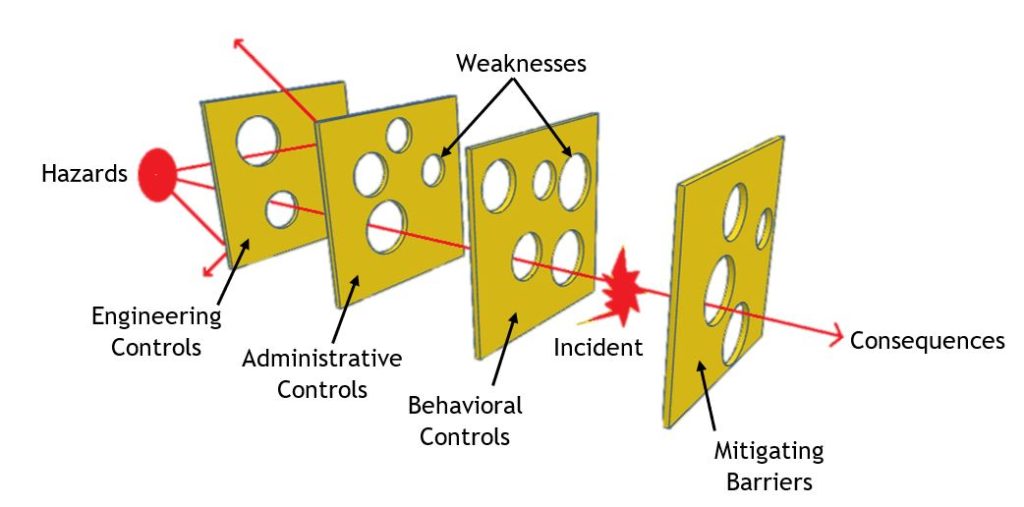

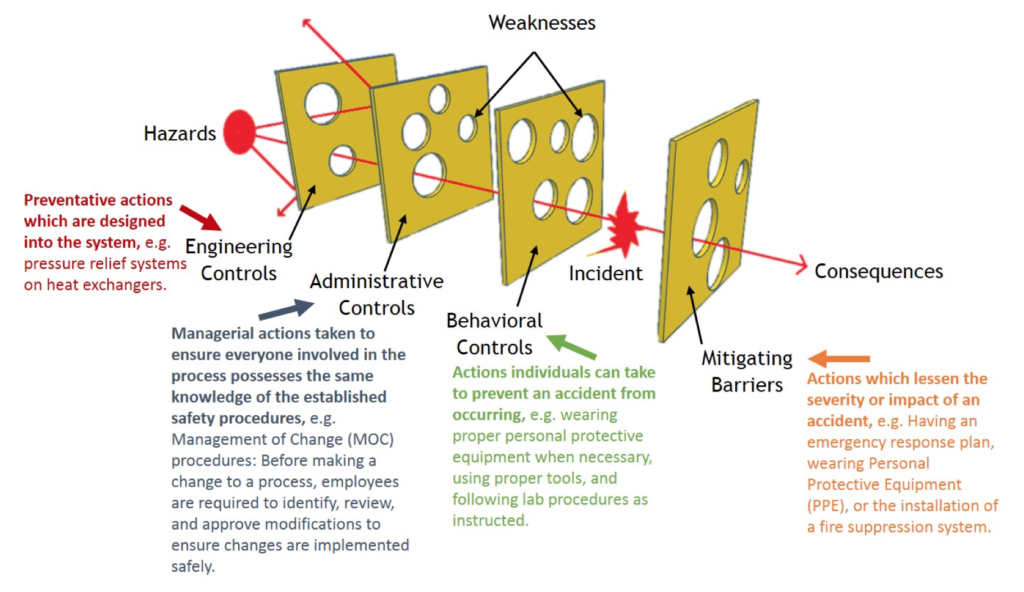

The Swiss cheese model is another risk assessment tool, one that offers a deeper understanding into the layers of protection for chemical processes. A layer of protection is either a preventative action that reduces the chance of an incident will occur, or a mitigating action that lessens the severity of an accident. These layers of protection can include using inherently safer designs, following proper lab procedures, wearing adequate personal protective equipment (PPE), or having an emergency response plan.

There are different levels or layers of protection, represented in the above figure as cheese slices. For an incident to occur, there must be vulnerability in each layer of protection, represented by holes in the slices of cheese. The size and number of holes in the cheese represent the relative lack of reliability of that layer. This model illustrates the importance of having redundant and strong protective layers so that hazards do not pass through multiple protective actions undetected and unresolved.

Understanding and implementing each protective level is important when running a chemical process:

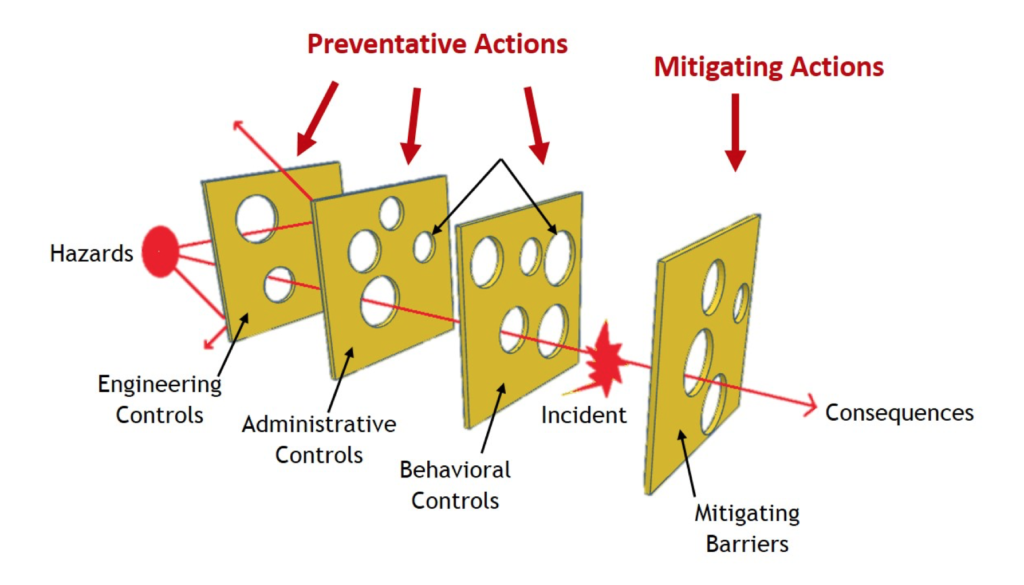

Engineering controls, administrative controls, and behavioral controls represent Preventative Actions designed to reduce the likelihood of an incident occurring, while mitigating barriers represent Mitigating Actions designed to lessen the impact or severity of an incident.

It’s important to recognize that all of these layers of protection will have some weaknesses. The main purpose of the Swiss Cheese model is to visualize how a hazard may be able to pass through the vulnerability of the many different measures in place.

Knowledge Check

There is a Swiss Cheese Model knowledge check quiz available.