Prepared in collaboration with Kara Steshetz

Introduction

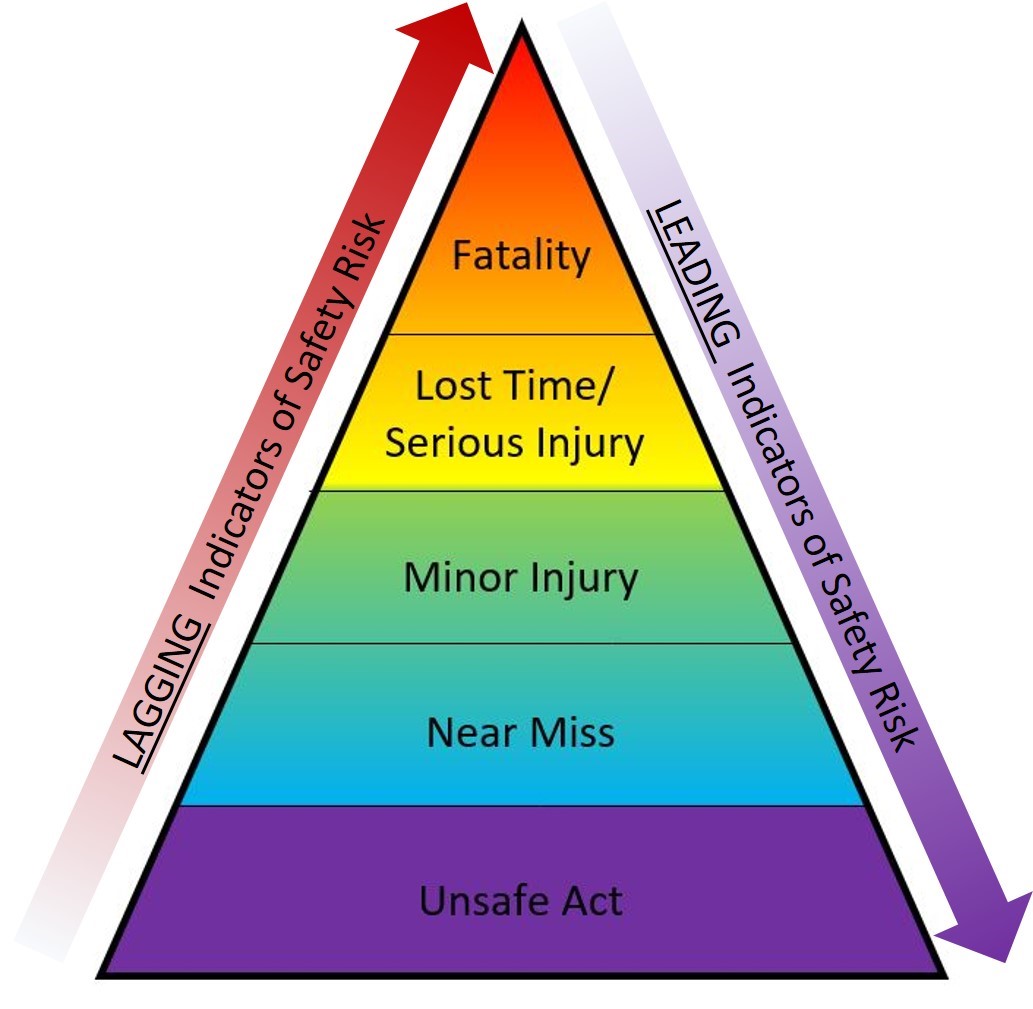

The purpose of this tutorial is to highlight how the smallest unsafe act can lead to a major accident. The process safety triangle is used to illustrate the different actions that can lead to an accident. This tool has a bottom up flow where each layer can be thought of as a preventative measure to the layer above it.

Components

- Fatality: An occurrence of death by accident.

- Lost Time/Serious Injury:

- The classification for an occupational injury which includes all disabling work injuries and non-disabling work injuries.

- These injuries include:

- eye injuries requiring treatment by a physician,

- fractures

- injuries requiring hospitalization

- loss of consciousness

- injuries requiring treatment by a doctor

- injuries requiring restriction of motion or work, or assignment to another job.

- Minor Injuries: Any injury sustained that does not meet one of the requirements of a serious injury listed above.

- For example, any injury that can be treated quickly on site, such as a bruise, a minor cut or scratch.

- Near Misses: An event in which an accident (that is, property damage, environmental impact, or human loss) or an operational interruption could have plausibly resulted if circumstances had been slightly different.

- Unsafe Acts: Any act that deviates from a generally recognized safe way or specified method of doing a job and which increases the probabilities for an accident.

Application to Process Safety

One of the main purposes of the process safety triangle is the illustration of how unsafe acts can lead to a major incident. The process safety triangle is also used to visualize the different layers of protection and help redesign systems to ensure better preventative practices. The bottom level, unsafe acts, is categorized as a leading metric. Leading metrics are preventative actions taken to avoid an incident from occurring. Unsafe behaviors of employees, such as not wearing personal protective equipment or the lack of protection layers for a system, are the fundamental causes of process safety incidents. The wider the base of your process safety triangle is the wider the top level is. This triangle illustrates how the more unsafe behaviors you have, the more likely a fatality from a process safety incident is to occur.

Near misses and the levels above it are categorized as lagging metrics. Lagging metrics are events that happen in a process that are reported for the improvement of the safety of the process. Analyzing past incidents has proven that if near misses are treated like injuries and incidents, such as reporting them, then the likelihood of a fatality from a process safety incident decreases. All past accidents have had warning signs (near misses) that indicated something needed to change and could have prevented the accident from occurring. Reporting near misses make others aware of a potential issue and allow for measures to be implemented to prevent the escalation to a process safety incident.

The key takeaways from the process safety triangle are that eliminating unsafe acts drastically reduce the risk of a process safety incident occurring. Reporting near misses allow for the process to be reviewed and improve to prevent injuries and fatalities from occurring.

Example of Process Safety Triangle

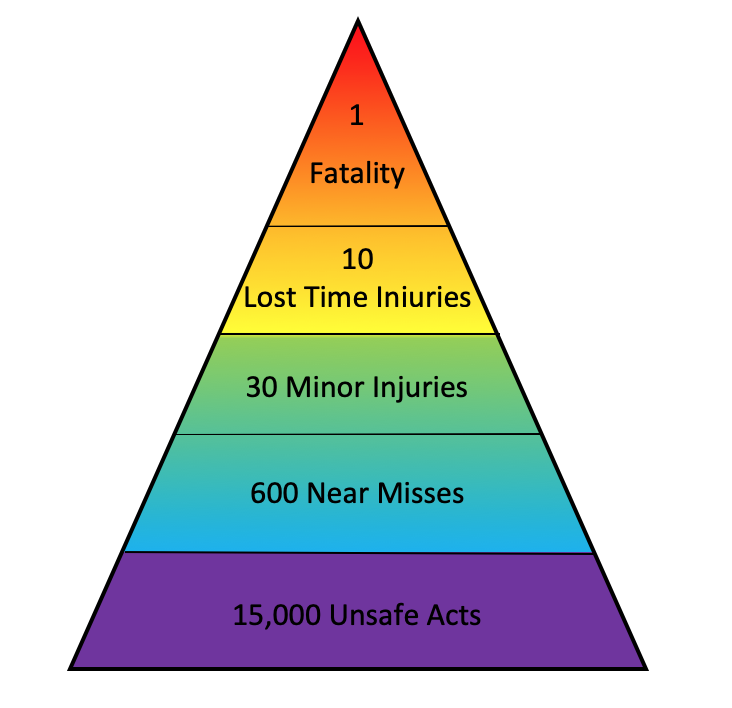

Below is an example of a process safety triangle with an estimation of each reported type of action on the triangle.

Knowledge Check

There is a Process Safety Triangle knowledge check quiz available.

References

- Center for Chemical Process Safety. “CCPS Process Safety Glossary.” American Institute of Chemical Engineers, www.aiche.org/ccps/resources/glossary

- Center for Chemical Process Safety. Process Safety Leading and Lagging Metrics. https://www.aiche.org/sites/default/files/docs/pages/CCPS_ProcessSafety_Lagging_2011_2-24.pdf

- Alliance and National Safety Council. Near Miss Reporting Systems. https://nsccdn.azureedge.net/nsc.org/media/site-media/docs/workplace/near-miss-reporting-systems.pdf

- US Legal, Inc. “US Legal.” Unsafe Act Law and Legal Definition, https://definitions.uslegal.com/u/unsafe-act/.