In the CAPECO explosion, the main gasoline storage tank was full, so an additional shipment of gasoline had to be stored in four smaller tanks using a highly manual process. One of the tanks had a broken level transmitter so “fill time” was manually calculated, and unfortunately overestimated.

The tank liquid overfilled and created a gasoline vapor plume, which found a spark and rapidly exploded. More information can be found at the CSB CAPECO Video and CSB CAPECO Report.

This section will investigate how a HAZOP study performed at the CAPECO facility could have exposed flaws in the facility’s protective systems. Exposing these hazards may have resulted in actions to close gaps and prevent the tank overfill that resulted in the catastrophic explosion.

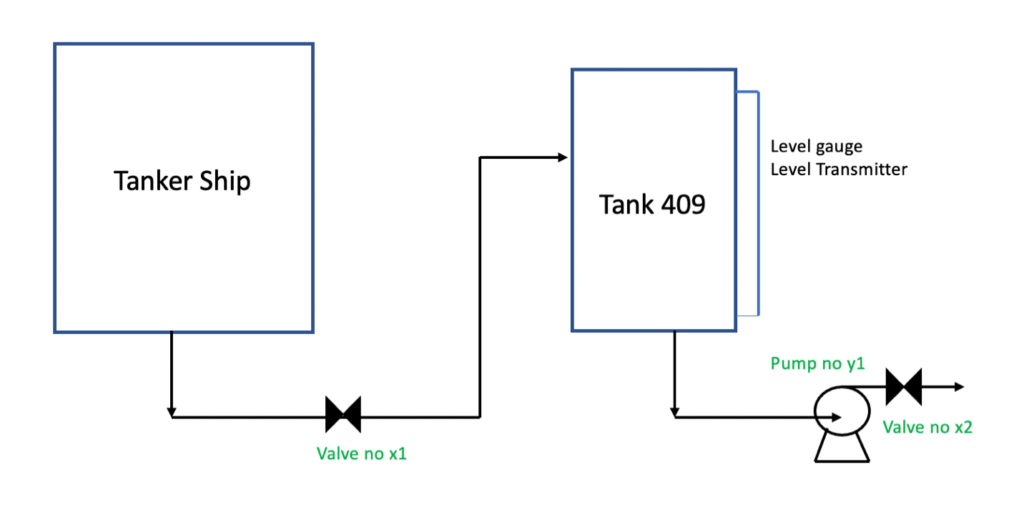

We will use Figure 2 below to carry out a HAZOP for the CAPECO explosion. We will consider a steady state scenario where gasoline was transferred from Tanker Ship to Tank 409 through a block valve X1. Pump Y1 was operating and withdrawing liquid from Tank 409. To monitor Tank 409 level, a level gauge and a level transmitter was installed.

1. Identify System

Consider the system to be the secondary gasoline storage tank 409. This vessel is the one that overfilled and resulted in the explosion. While the system being considered is Tank 409, the surrounding valves X1 and X2 along with pump Y1 will be important for considering causes of different deviations for this system.

2. Choose a Guide Word and process parameter

We illustrate two scenarios below: (1) no flow and (2) more flow

#1 Guide Word: No, Process Parameter: Flow

The engineer would consider a scenario where there was no flow from the tanker vessel to the storage tank. They would need to assess what does a no flow scenario means, what could have caused the scenario, and what are the consequences and potential safety implications. After determining the potential consequences, the engineer would look to see what safeguards were in place to prevent them and what further actions could be taken to ensure safety.

#2 Guide Word: More, Process Parameter: Flow

The deviation more flow would describe an incident where more fluid than expected was offloaded into the tank. This scenario was the one that occurred in the CAPECO incident.

3. Go to Step 2, and repeat for all relevant guide words

Click on the button to check the results

If the content is not fully displayed, please reduce the page size

| GUIDEWORD + PARAMETER = DEVIATION | CAUSES | CONSEQUENCES | SAFEGUARDS | RECOMMENDATIONS |

|---|---|---|---|---|

| No Inlet Flow to Tank 409 | ||||

| More Inlet Flow to Tank 409 | ||||

| Less Inlet Flow to Tank 409 | ||||

| More Level in Tank 409 | ||||

| Less Level in Tank 409 |

4. Write a short analysis after completing the HAZOP

Analysis: This tank was not equipped with an automatic overfill protection system that would have stopped the flow as soon as it detected overfill or diverted the flow to another tank. After considering the consequences caused by more flow, the engineers at the CAPECO facility may have determined that their facility is ill-equipped to measure and react to additional flow.

5. Gap Identification & Next Steps

Once we have identified all hazards, the next step is to apply a Layers of Protection Analysis (LOPA) to the highest risk and impact scenario. These safeguards could include any of the following:

- Functional level transmitter communicating with an automatic flow diverter

- Alarm system alerting when there is a high level in the tank

- Alternative secondary containment besides the diked region

- Gas detector in the vicinity of the tank farm

- Total organic carbon composition detectors on inlet to water treatment facility

If implemented, each of these layers of protection could have prevented this event from occurring.

More information on how to conduct a LOPA can be found in the LOPA Tutorial.